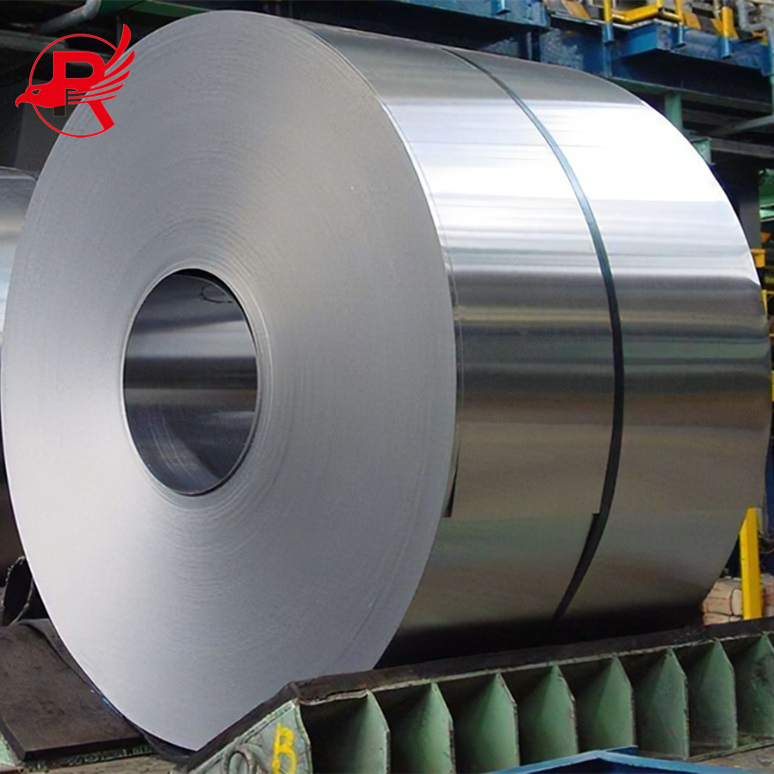

ცხელი ნაგლინი Aisi 309 310 310S 321 უჟანგავი ფოლადის ხვეული

| პროდუქტის დასახელება | 309 310 310S 321 უჟანგავი ფოლადის ხვეული |

| შეფასებები | 201/EN 1.4372/SUS201 |

| სიმტკიცე | 190-250HV |

| სისქე | 0.02 მმ-6.0 მმ |

| სიგანე | 1.0 მმ-1500 მმ |

| კიდე | ჭრილი/დაფქვა |

| რაოდენობრივი ტოლერანტობა | ±10% |

| ქაღალდის ბირთვის შიდა დიამეტრი | Ø500 მმ ქაღალდის ბირთვი, სპეციალური შიდა დიამეტრის ბირთვი და ქაღალდის ბირთვის გარეშე, მომხმარებლის მოთხოვნით |

| ზედაპირის დასრულება | NO.1/2B/2D/BA/HL/დავარცხნილი/6K/8K სარკე და ა.შ. |

| შეფუთვა | ხის პალეტა/ხის ყუთი |

| გადახდის პირობები | 30% TT დეპოზიტი და 70% ბალანსი გადაზიდვამდე, 100% LC ადგილზევე |

| მიწოდების დრო | 7-15 სამუშაო დღე |

| MOQ | 200 კგ |

| გადაზიდვის პორტი | შანხაი/ნინგბოს პორტი |

| ნიმუში | 309 310 310S 321 უჟანგავი ფოლადის კოჭის ნიმუში ხელმისაწვდომია |

201 არის დაბალნახშირბადიანი უჟანგავი ფოლადი, რომელიც გამოირჩევა შესანიშნავი შედუღებადობით, კარგი კოროზიისადმი მდგრადობით და მაღალი სიმტკიცით. ის იდეალური მასალაა მრავალფეროვანი გამოყენებისთვის, მათ შორის საკვების გადამამუშავებელი მოწყობილობებისა და ქიმიური დამუშავების მოწყობილობებისთვის.

ქვემოთ მოცემულია უჟანგავი ფოლადის კოჭების ყველაზე გავრცელებული გამოყენების რამდენიმე ჩამონათვალი:

1. საკვების გადამამუშავებელი და ქიმიური დამუშავების აღჭურვილობა

2. ნავთობისა და გაზის მრეწველობა

3. საზღვაო გამოყენება

შენიშვნა:

1. უფასო შერჩევა, 100% გაყიდვების შემდგომი ხარისხის უზრუნველყოფა, ნებისმიერი გადახდის მეთოდის მხარდაჭერა;

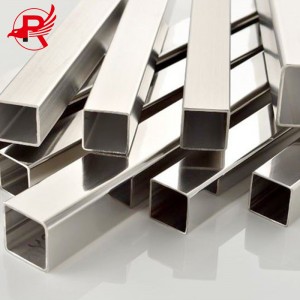

2. მრგვალი ნახშირბადოვანი ფოლადის მილების ყველა სხვა სპეციფიკაცია ხელმისაწვდომია თქვენი მოთხოვნის შესაბამისად (OEM და ODM)! ქარხნულ ფასს მიიღებთ ROYAL GROUP-ისგან.

უჟანგავი ფოლადის ხვეულის ქიმიური შემადგენლობა

| ქიმიური შემადგენლობა % | ||||||||

| კლასი | C | Si | Mn | P | S | Ni | Cr | Mo |

| 201 | ≤0 .15 | ≤0 .75 | 5. 5-7. 5 | ≤0.06 | ≤ 0.03 | 3.5 -5.5 | 16.0 -18.0 | - |

| 202 | ≤0 .15 | ≤l.0 | 7.5-10.0 | ≤0.06 | ≤ 0.03 | 4.0-6.0 | 17.0-19.0 | - |

| 301 | ≤0 .15 | ≤l.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 6.0-8.0 | 16.0-18.0 | - |

| 302 | ≤0 .15 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 8.0-10.0 | 17.0-19.0 | - |

| 304 | ≤0 .0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 8.0-10.5 | 18.0-20.0 | - |

| 304L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0-13.0 | 18.0-20.0 | - |

| 309S | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0-15.0 | 22.0-24.0 | - |

| 310S | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.035 | ≤ 0.03 | 19.0-22.0 | 24.0-26.0 | |

| 316 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 |

| 316L | ≤0 .03 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0 - 15.0 | 16.0 -1 8.0 | 2.0 -3.0 |

| 321 | ≤ 0.08 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0 - 13.0 | 17.0 -1 9.0 | - |

| 630 | ≤ 0.07 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | 3.0-5.0 | 15.5-17.5 | - |

| 631 | ≤0.09 | ≤1.0 | ≤1.0 | ≤0.030 | ≤0.035 | 6.50-7.75 | 16.0-18.0 | - |

| 904L | ≤ 2.0 | ≤0.045 | ≤1.0 | ≤0.035 | - | 23.0·28.0 | 19.0-23.0 | 4.0-5.0 |

| 2205 | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.030 | ≤0.02 | 4.5-6.5 | 22.0-23.0 | 3.0-3.5 |

| 2507 | ≤0.03 | ≤0.8 | ≤1.2 | ≤0.035 | ≤0.02 | 6.0-8.0 | 24.0-26.0 | 3.0-5.0 |

| 2520 | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.045 | ≤ 0.03 | 0.19 -0.22 | 0. 24 -0. 26 | - |

| 410 | ≤0.15 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | - | 11.5-13.5 | - |

| 430 | ≤0.1 2 | ≤0.75 | ≤1.0 | ≤ 0.040 | ≤ 0.03 | ≤0.60 | 16.0 -18.0 | |

ცივი გლინვისა და გლინვის შემდეგ ზედაპირის გადამუშავების სხვადასხვა დამუშავების მეთოდის მეშვეობით, უჟანგავი ფოლადის კოჭების ზედაპირის დასრულებას შეიძლება ჰქონდეს სხვადასხვა ტიპი.

უჟანგავი ფოლადი მრავალმხრივი და გამძლე მასალაა, რომელიც გამოიყენება მრავალფეროვან დანიშნულებაში, სამზარეულოს ჭურჭლიდან დაწყებული სამშენებლო მასალებით დამთავრებული. უჟანგავი ფოლადის ხვეულები მრავალი პროდუქტის ძირითადი კომპონენტია, რადგან ისინი უზრუნველყოფენ მასალის კონკრეტული ფორმებისა და ზომების მიცემას. მოდით, უფრო დეტალურად განვიხილოთ უჟანგავი ფოლადის ხვეულების წარმოების პროცესი.

1. დნობა და რაფინირება: წარმოების პროცესის პირველი ეტაპია უჟანგავი ფოლადის დასამზადებლად გამოყენებული ნედლეულის - როგორც წესი, რკინის მადნის, ნიკელის, ქრომის და სხვა ლითონების - დნობა. ეს ხდება ღუმელში ან ღუმელში, როგორც წესი, ელექტრორკალის ან ინდუქციური ღუმელის გამოყენებით. შედეგად მიღებული გამდნარი ლითონი შემდეგ რაფინირდება მინარევების მოსაშორებლად და შენადნობის სათანადო შემადგენლობის უზრუნველსაყოფად.

2. ჩამოსხმა: ლითონის დამუშავების შემდეგ, ის ყალიბებში ასხამენ ჩამოსხმული ნაჭრების ფორმირებისთვის. ფილას შეიძლება ჰქონდეს რამდენიმე ინჩის სისქე და 20 ტონა ან მეტი წონა. ჩამოსხმის ეს პროცესი, როგორც წესი, უწყვეტი ჩამოსხმის მანქანაში ხორციელდება, რაც უზრუნველყოფს მასალის მუდმივ დინებას და უფრო მეტ ეფექტურობას.

3. ცხელი გლინვა: შემდეგ ფილა თბება და გადის ცხელი გლინვის წისქვილების სერიაში. გლინვის წისქვილები აღჭურვილია ლილვაკებით, რომლებიც აწვებიან და აყალიბებენ ფოლადს უფრო თხელ ფურცლებად ან ზოლებად. ცხელი გლინვის პროცესს შეუძლია წარმოქმნას 1000 გრადუს ცელსიუსზე მეტი ტემპერატურა, რაც საშუალებას იძლევა მასალის ფორმირება მოხდეს დაზიანების გარეშე.

4. ცივი გლინვა: ცხელი გლინვის პროცესის დასრულების შემდეგ, უჟანგავი ფოლადი ცივად გლინდება სასურველი სისქისა და ზედაპირის დამუშავების მისაღწევად. ეს გულისხმობს მასალის გატარებას ცივი გლინვის წისქვილების სერიაში, რომლებიც კიდევ უფრო აწვებიან და აყალიბებენ ფოლადს. ცივი გლინვა ასევე ზრდის უჟანგავი ფოლადის სიმტკიცეს და გამძლეობას, რაც მას უფრო მდგრადსა და გამძლეს ხდის.

5. გამოწვა: მას შემდეგ, რაც უჟანგავი ფოლადი ცივად არის გაგორებული სასურველ სისქემდე, იგი თერმული დამუშავების დროს გამოწვავდება. ეს გულისხმობს მასალის მაღალ ტემპერატურაზე გაცხელებას და შემდეგ დროთა განმავლობაში ნელა გაგრილებას. გამოწვა ხელს უწყობს უჟანგავი ფოლადის დარბილებას და ზრდის მის პლასტიურობას, რაც აადვილებს ხვეულების ან სხვა ფორმების ფორმირებას.

6. ჭრა და დახვევა: და ბოლოს, უჟანგავი ფოლადი იყოფა ზოლებად — იჭრება თხელ ზოლებად — შემდეგ იხვევა ტრანსპორტირებისა და შენახვისთვის. ეს პროცესი, როგორც წესი, ხორციელდება სპეციალიზებული აღჭურვილობის გამოყენებით, როგორიცაა საჭრელი და დახვევის აპარატები. შემდეგ სპირალი შეიძლება გაიგზავნოს დამამზადებელთან ან დამამზადებელთან, რომელიც გამოიყენებს მასალას მზა პროდუქტის შესაქმნელად.

უჟანგავი ფოლადის კოჭის სტანდარტული საზღვაო შეფუთვა

სტანდარტული ექსპორტის საზღვაო შეფუთვა:

წყალგაუმტარი ქაღალდის შესახვევი + PVC ფირი + სამაჯურის შესაკრავი + ხის პალეტა ან ხის ქეისი;

თქვენი მოთხოვნის შესაბამისად მორგებული შეფუთვა (შეფუთვაზე დასაბეჭდად მისაღებია ლოგო ან სხვა შინაარსი);

სხვა სპეციალური შეფუთვა შეიქმნება მომხმარებლის მოთხოვნის შესაბამისად;

ტრანსპორტი:ექსპრეს (ნიმუშის მიწოდება), საჰაერო, სარკინიგზო, სახმელეთო, საზღვაო გადაზიდვები (FCL ან LCL ან ნაყარი)

კითხვა: ხართ თუ არა ua-ს მწარმოებელი?

A: დიახ, ჩვენ ვართ მწარმოებელი. ჩვენ გვაქვს საკუთარი ქარხანა, რომელიც მდებარეობს ტიანძინში, ჩინეთი.

კითხვა: შემიძლია თუ არა საცდელი შეკვეთა მხოლოდ რამდენიმე ტონა?

A: რა თქმა უნდა. ჩვენ შეგვიძლია ტვირთის გადაზიდვა თქვენთვის LCL სერვისით (ნაკლები კონტეინერის დატვირთვა)

კითხვა: თუ ნიმუში უფასოა?

A: ნიმუში უფასოა, მაგრამ მყიდველი იხდის ტვირთის საფასურს.

კითხვა: ხართ თუ არა ოქროს მომწოდებელი და ვაჭრობის გარანტიას ახორციელებთ?

A: ჩვენ შვიდი წლის განმავლობაში ვართ ოქროს მიმწოდებლები და ვიღებთ სავაჭრო გარანტიას.